| Rg7 / CuSn7ZnPb | Round bars, square bars, flat bars, hexagon, round tubes, bushings |

| G Bz 12 / CuSn12 | Round bars, square bars, flat bars, hexagon, round tubes, bushings |

| CuAl10Ni5Fe4 / BA1054 | Round bars, square bars, flat bars, round tubes, bushings |

| CuPb15Sn / brąz ołowiowy | Round bars, bushings |

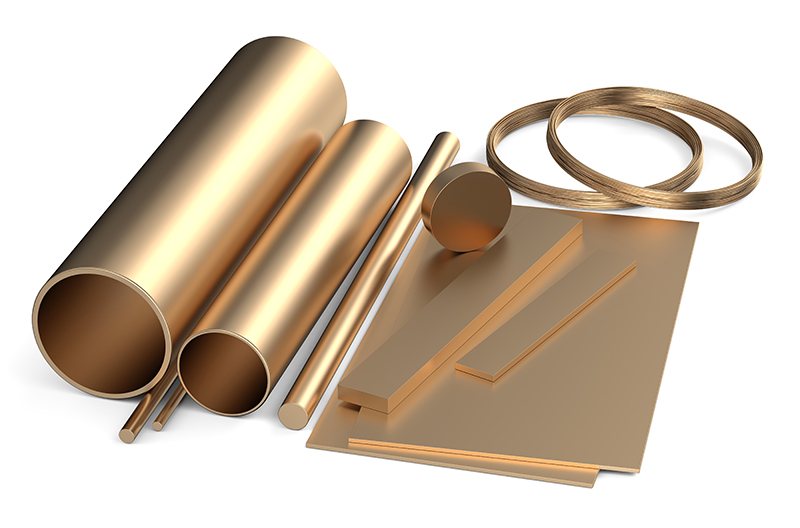

*BRONZE

PROPERTIES

Density: 7,5–9,3 g/cm³,

Melting point: 940–1084 °C,

The most commonly used alloys: tin, aluminum, beryllium, silicon and lead. The name bronze comes from the main alloying additive.

Bronzes are divided into two groups, i.e. bronze for forming and foundry bronze.

Foundry bronzes are characterized by resistance to corrosion, abrasion and good machinability.

Molding bronzes are characterized by high durability, corrosion and abrasion resistance. Smaller amounts of alloying additives are used for foundry bronzes in order to obtain better plastic properties of alloys.

Foundry bronzes are often multi-component alloys containing, in addition to tin, other elements such as zinc, aluminum, lead and phosphorus.

Their structure consists of grains.

Foundry bronzes are known for resistance to corrosion, abrasion and good machinability.

*BRONZE

AVAILABLE FROM WAREHOUSES

*BRONZE

SPECIES

| PN | PN-EN | DIN | PROPERTIES AND APPLICATION | ||

|---|---|---|---|---|---|

| Symbol | Number | Symbol | Number | ||

| TIN BRONZE | |||||

| B4 | CuSn4 | CW450K | CuSn4 | 2.1016 | Tin bronze alloy is characterized by elasticity and resistance to abrasion and corrosion. It subjects to soldering, welding and cold working. The alloy is used for production of wear-resistant parts, testing and measuring instruments and springs. With high speeds the alloy of bronze CuSn12 is characterized by good sliding properties. For this reason it is mainly used for production gears. |

| B6 | CuSn6 | CW452K | CuSn6 | 2.1020 | |

| B8 | CuSn8 | CW453K | CuSn8 | 2.1030 | |

| B10* | CuSn10 | CC480K | G-CuSn10 | 2.1051 | |

| − | CuSn12 | − | Gbz12 | − | |

| TIN-PHOSPHORUS BRONZE | |||||

| B101* | CuSn10P | – | – | – | The main characteristics of phosphor bronze alloy are tin-abrasion resistance, corrosion resistance and high mechanical loads. Phosphor bronze alloy is used for production of machine parts exposed to heavy load, quick turnover machine parts , corrosion as well as poorly lubricated. |

| TIN-LEADED BRONZE | |||||

| B1010* | CuSn10Pb10 | CC495K | G-CuPb10Sn | 2.1177 | Tin-lead alloy is used for production of bearings and rubbing parts of machines that operate on high speeds and pressures. |

| TIN-ZINC-LEAD BRONZE | |||||

| B555 | CuSn5Zn5Pb5 | CC491K | G-CuSn5ZnPb/RG5 | 2.1096 | Tin-Zinc- Lead alloy is characterized by high resistance to abrasion and corrosion. It is mainly used in tool industry for production of bearings, automotive industry as well as for manufacturing of machinery parts, vehicles parts, engines and tractors. |

| B444 | CuSn4Pb4Zn4 | CW456K | – | – | |

| RG7 | CuSn7Zn4Pb7 | CC493K | – | – | |

| ALUMINIUM BRONZE | |||||

| BA8 | CuAl8 | − | CuAl8 | 2.0920 | Aluminum bronze alloy is characterized by high resistance to corrosion, abrasion and impact. Due to these properties they are used in the chemical industry, transportation, shipbuilding and aerospace. They are used for production of elements that work in seawater, highly loaded parts of machines and engines, sliding contacts, parts of bearings, filters, bolts, fittings and coins. |

| BA1032 | CuAl10Fe3Mn2 | CW306G | CuAl10Fe3Mn2 | 2.0936 | |

| BA1054 | CuAl10Ni5Fe4 | CW307G | CuAl10Ni5Fe4 | 2.0966 | |

| BA93* | CuAl9Fe3 | − | − | − | |

| BA83 | CuAl8Fe3 | CW303G | CuAl8Fe | 2.0932 | |

| SILICON BRONZE | |||||

| BK31 | CuSi3Mn1 | CW116C | CuSi3Mn1 | 2.1525 | Silicon bronze is characterized by high elasticity, corrosion resistance and susceptibility to welding as well as processing of cold and hot. It is used in chemical industry and machinery for the production of elastic, weld able nets and parts exposed to wear. |

| BK331* | CuSi3Zn3Mn1 | – | – | – | |