Stainless steel is all steels featuring high corrosion resistance, except for heat-resistant ones. Melting point 1510 ° C,

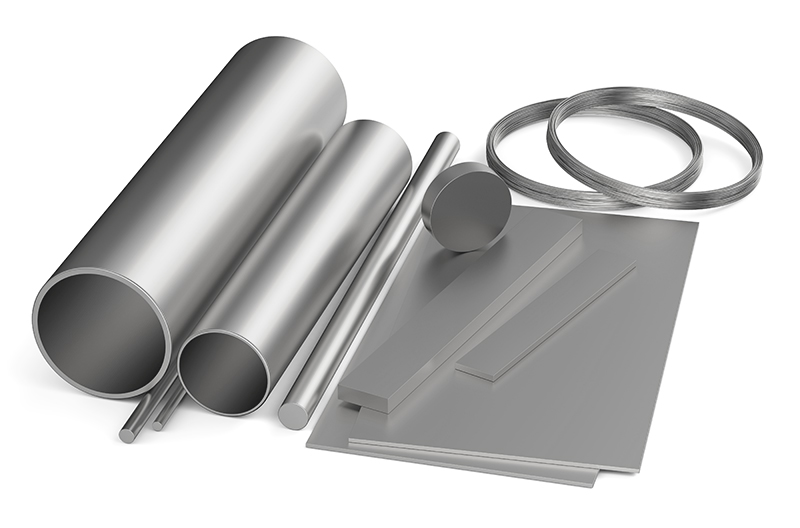

Plastic material suitable for processing,

Stainless steel is a group of steels with special physicochemical properties, resistant to corrosion by: water, atmospheric agents, diluted acids, alkaline solutions.

Stainless steel, acid resistance and heat resistance are obtained by adding chromium and nickel, molybdenum in appropriate amounts, as well as in the case of heat-resistant steels, aluminum, silicon and cerium. Currently, corrosion-resistant steels are divided into two groups: stainless steel and heat-resistant steel.

Used at temperatures up to 500 ° C. Numbering in the range 1.40 .. – 1.45 ..

Heat resistant steels (including creep resistant) are steels that exhibit high corrosion resistance, including oxidation (scale formation) at temperatures above 500 ° C. Heat-resistant steels are also required to have unchanged mechanical properties under these conditions. Numbering in the range 1.47 ..- 1.48 ..

The main properties of the above-mentioned steel are: corrosion resistance in various environments, resistance to high temperatures, low thermal expansion, stiffness, strength, durability, ease of processing and joining.