| GG-15/EN-GJL-150, GG-20/EN-GJL-200, GG-25/EN-GJL-250, GG-30/EN-GJL-300, |

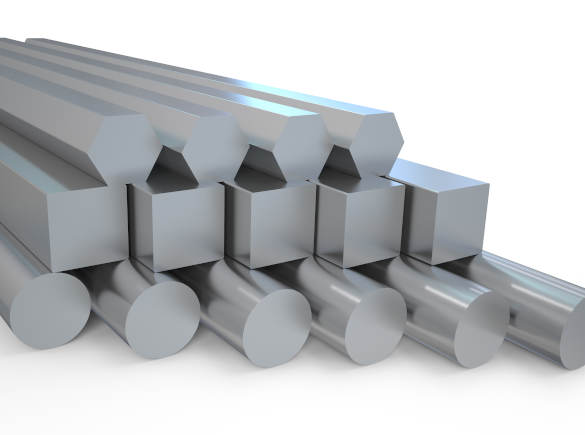

Sheet, plates, round bars , square bars , flat bars, hexagon, bushings |

| GG-40/EN-GJS-400, GG-45/EN-GJS-450, GG-50/EN-GJS-500, GG-60/EN-GJS-600, GG-70/EN-GJS-700, |

Sheet, plates, round bars , square bars , flat bars, hexagon, bushings |

*IRON CAST

PROPERTIES

Cast iron – high carbon iron alloy with carbon, usually also with silicon, manganese, phosphorus, sulphur and other components. It contains from 2.11 to 6.67% carbon in the form of cementite or graphite. The occurrence of a specific phase of carbon depends on the cooling rate and chemical composition of the alloy. Slow cooling promotes the release of graphite. Also alloying additives play a role in this process.

The density is 7,85 kg/dm3,

Melting point 950 oC,

Soft metal, characterized by very good thermal and electrical conductivity.

The density is 7,85 kg/dm3,

Melting point 950 oC,

Soft metal, characterized by very good thermal and electrical conductivity.

*IRON CAST

APPLICATION

Grey cast iron:

It is a common material used for the production of non-load-bearing castings, such as radiators, bathtubs, washbasins, furnace parts (grates, doors), as well as machine parts – ingot moulds, car cylinders, pistons.

It is a common material used for the production of non-load-bearing castings, such as radiators, bathtubs, washbasins, furnace parts (grates, doors), as well as machine parts – ingot moulds, car cylinders, pistons.

Ductile cast iron:

It is used for production of many automotive parts (camshafts, crankshafts, steering components), gears, machine tool spindles and valve parts.

*IRON CAST

AVAILABLE FROM WAREHOUSES

*IRON CAST

SPECIES

| DIN | EN | BS | ||

|---|---|---|---|---|

| Symbol | Rm (MPa) | Symbol | Rm (MPa) | |

| Żeliwo szare | ||||

| GG-15 | EN-GJL-150 | 150 | 150 | 150 |

| GG-20 | EN-GJL-200 | 200 | 200 | 200 |

| GG-25 | EN-GJL-250 | 250 | 250 | 250 |

| GG-30 | EN-GJL-300 | 300 | 300 | 300 |

| Żeliwo sferoidalne | ||||

| GGG-40 | EN-GJS-400 | 400 | 400 | 400 |

| GGG-45 | EN-GJS-450 | 450 | 450 | 450 |

| GGG-50 | EN-GJS-500 | 500 | 500 | 500 |

| GGG-60 | EN-GJS-600 | 600 | 600 | 600 |

| GGG-70 | EN-GJS-700 | 700 | 700 | 700 |

Oznaczenia żeliwa:

EN-GJL – żeliwo szare,

EN-GJS – żeliwo sferoidalne,

G – materiał odlewany,

J – żeliwo,

S – grafit w postaci kulek,

L – grafit w postaci płatków.